Invader 22

I've a feeling these may be very similar internally to the Barton 'Nautalus' range. Maybe the springs are the same ?

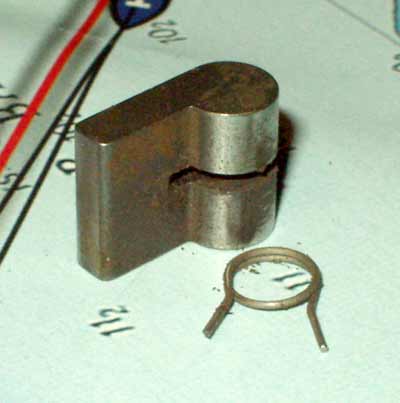

base unit and main spindle

easing the spring out from its groove - then slide up the cam

Not much wear here on either the cams or the springs.

Below

The centre spindle sits in the base housing, held by a single circlip at the base. The white centre lining appears to be a composite similar to the black material - and this was still a perfect fit. The nylon washer under the ractchet was swelled, causing the circlip to bind.

The top steel ratchet here locates with the top cams - providing the reverse ratchet for the winch handle - and clockwise drives the winch drum. The lower black moulded ratchet on the base housing locates to the lower cams at the base of the outer drum unit - and is the main ratchet for the winch body.

The port side was stiff - so had a go at that one first.

The top cap is held on by a circular split circlip - no problem getting the cap off. In theory, the body should now lift off - no such luck.

Essentially. you need to get the top unit off to expose the fixing set screws. These winches are made from a very hard nylon/composite type material - and the main roller bearing is a nylon roller cage unit.

Fortunately five of the fixing nuts came free without spinning - and I managed to reach the last with an angle grinder - eventually getting it off intact. Figured it better to that than force or lever anything before I could see what exactly was going on.

I then managed to tap the centre spindle/base unit out of the nylon roller bearing. This is not ideal, since it is the spring cams at the base of the outer shell that the bearing is forcing itself against.

Once the top unit is slid off - it's easy to remove the cams/springs - you just need fine point such as a large needle to prise the spring end out of it's groove, then the cam slips out. Watch the spring ! they're small !

Once I had it separated - with the cams out, the roller bearing would fit fine into the top unit - or over the base spindle - but try to put the two together and it was binding.

Essentially these seem to be maintenance free units - certainly the nylon bearing set in composite material does not want to see oil or grease. Maybe the cams could be greased.

Even after a thorough clean this bearing was binding tight between the two units - so something must have swelled - I suspect the nylon bearing.

I've no idea yet whether spares are available - would be nice to have new springs - but most of it looks in good nick.

As below - I eased the spidle sides until they were a nice sliding fit. Difficult stuff to work - but found a small sharp cabinet scraper, combined with wet/dry between scrapes did the job. Its not as if it has to spin at high speeds.

The main spindle is simply held by a circlip at the base - again, this was binding. The culprit was the nylon washer, acting as a spacer to the circlip. So I lapped off the top of the base spindle slightly.

I suspect most of the problem here is the swelling of the nylon parts from mineral based oils. Will stick to silicone grease on the cams and Holt silcone/ptfe lube on the rest.

Now for the starboard one - with a little extra wisdom. - Also, now that they are off, I think I'll re-set them up on sloping baseplates - with a corresponding sloped backing plate. These are easy to make with a bit of white gel coat, then filled up with a mix of glass/filler. Found the ideal mould today - B&Q pot plant tidy's - right size, right shape, smooth plastic and only 38 pence each ! ( see here )

This will improve the lead from the genoa tracks - which at present is not good.