|

|

|

Off with Her Head - Off with Her Head !

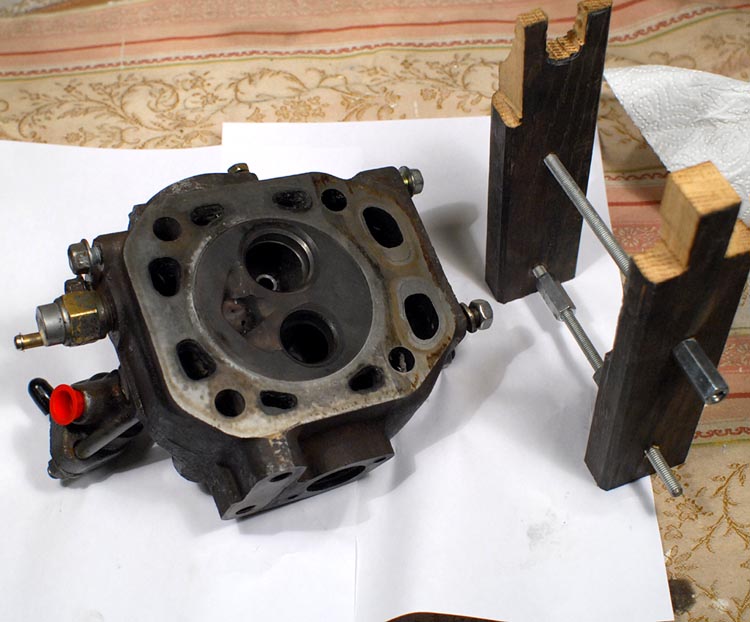

The inlet valve was like new - 20 years operation ! - I think this engine has done less hrs than I think somehow over that time. It was re-engined in 1993. Exhaust very slightly pitted on part of the seat, good on the valve - inlet almost perfect. Little carbon build up. Piston head good - bore seems fine. Took the head into a local engine refurb palce ( old fashioned type firm ) and they reckoned the valve/guide fit was ok. Just need a slight lap in. If I wanted to fit new guides it would be around £20 to press them - £40 for the pair new parts - then if new valves around £40 for the pair again. Already gone £40 on new valves stem seals, rocker gasket and precombustion chamber packings ( I already had the heat and top seals ) It all sort of pointed to merely a shot head gasket. There were signs of it leaking into the tappet gallery. Also the waterway by the temp sender was blocked ( the small hole in the gasket locates here ) so flow was resticted around that area - my overheating problem possibly. With it home on the bench - I really wanted to take out and check the preconbustion chamber. I had second thoughts, as it looked like it might be a problem. Anyway - I made crude brass 'mini slide hammer' to ease it up. It was fairly loose - but neeeded a 'little' tap up. The Chamber end of the precom - unit, that sticks out into the combustion chamber. There is the tinies bit of pitting just between the top two holes - otherwise exceedingly good condition.

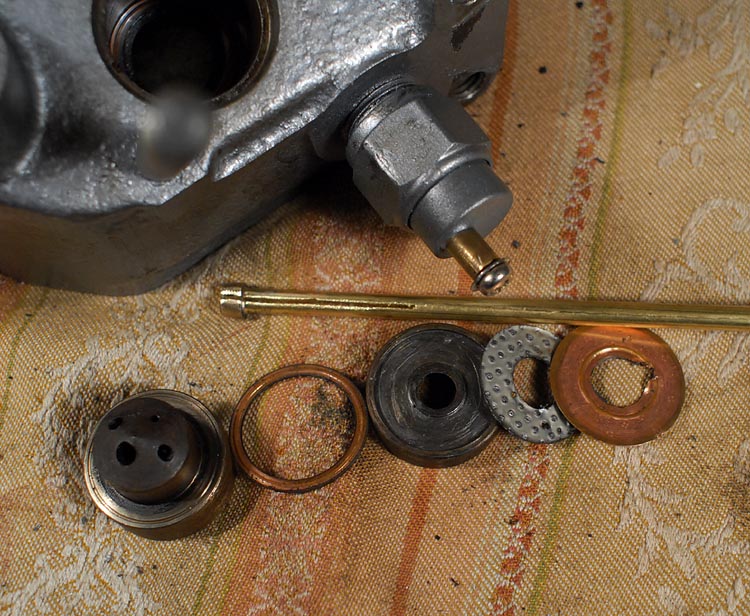

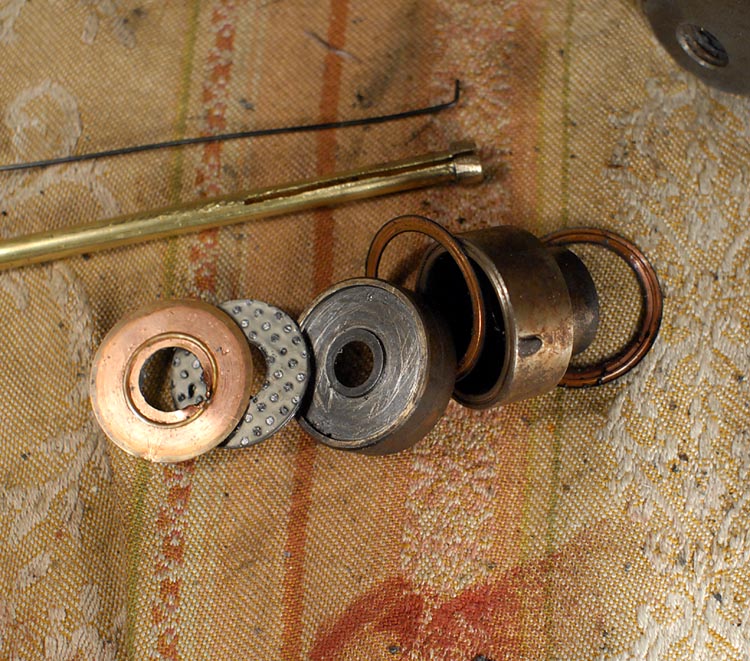

As they came out before cleaning up. The 'special tools' - Ha - did at least work. The brass rod springs through the hole and can be prised open with a small wedge. The other end had a stop end soldered on - so one can use a large adjustable over the bar to tap upwards. The other hook is a piece of high tensile wire ( stiff ) to hook up the edge of the copper washers. They are very thin - almost like shims so are hard to get loose. The ring on the shim to the left is imprinted from the base of the injector - so has to be replaced if the injector is ever removed. Similar with the other shims. This show the lug on the bottom unit that slides down the groove. The top packer is expensive for what it is - £ 8 - and the heat shield is about £ 7 - the other two are £ 2 each. A new top unit is affordable - about £25 - the lower one is mortgagable at around £145 ! They are extremely high quality things though. After all they are in the conbustion chamber of a deisel for twenty years. Hopfully I can get the ultrsonically cleaned - great for things like that. . So - I already had fished out the heat washer and the copper thin penny washer under the injector. Easy with the head off - a pig with it in situ. The heat washer is the same stuff as a the exhaust gasket - grey thick graphite type thing with a metal inner layer. If you have to get one out with the head on - scrape away the top layer of grey soft stuff - this exposes the metal. It has small holes in it - so you can spike through one and it will hook up. You can then scrape away the rest of the soft silver stuff ! All that with the hole on the middle plugged - to stop it falling down into the pre-com chamber !! Almost impossible. Better really to try to lift the top cap off up the injector bore - being careful not to dislodge the lower unit. To remove the lower precom unit just from above, with the head on - would be very difficult. Once the top half is out - you are left with the 'mousey in the hole' thing that pokes into the head between the valves. This lower half has a small lug that slides in a groove in the bore. Under it - and above it are two thin copper shims which must be repaced. Its a solid thing - so a small tap with a bit of wood is not going to harm it. Don't whack the hell out of it though - its pricey. It slid up the bore easily once free. Its a fiddle to pick out the washer left in situ - so I made the small wire hook in the pic. All cleaned up now - head rust treated and repainted. New seals on order from French Marine - plus the two copper packing washers for the chamber. I have the rest of the injector packings spare -the heat washer and the large copper shim. Generally in surprisingly good shape after twenty years in situ ! When refitting - be careful with the injector and its high pressure pipe. I located the injector with the new packings and its top clamp - just hand tight so it was still free to spin around - then put on the pipe nut hand tight, both to the injector and to the pump. I then tightened the injector down to torque ( tightening just a lttle on each side until there ) then I tightened up the pipe nuts either end. Once the pump and the injector were up tight - I then fitted the clamp nuts on the Alt bracket. Continued - head off 2 Geoff - Uphill moorings, Dec 2013 |

|